Research: Engineering Cyanobacteria

Indigenous cyanobacteria as cell factories for biomanufacturing

Cyanobacteria can fix atmospheric CO2 via photosynthesis using sunlight and minimal nutrient input. These capabilities make them attractive platforms for biomanufacturing and carbon capture. Cyanobacteria can be cultivated on a large scale, either in outdoor ponds or in photobioreactor vessels, making them ideal cell factories for sustainable production of diverse chemicals and fuels.

-

Isolation and characterization of fast-growing cyanobacteria

Cyanobacteria can fix atmospheric CO2 via photosynthesis using sunlight and minimal nutrient input. These capabilities make them attractive platforms for biomanufacturing and carbon capture. Cyanobacteria can be cultivated on a large scale, either in outdoor ponds or in photobioreactor vessels, making them ideal cell factories for sustainable production of diverse chemicals and fuels.

Over the last decade, we gathered a foundational understanding of the physiology and metabolism of these strains to unlock their potential as cell factories.

-

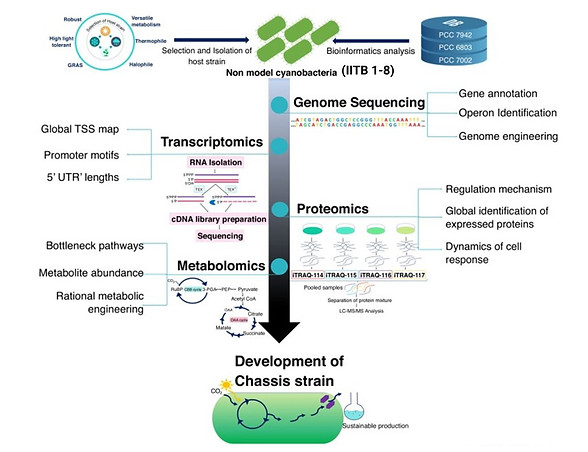

We applied multi-omics techniques (genomics, proteomics, transcriptomics, and metabolomics), as well as 13C-metabolic flux analysis, to gain a systems-level view and detailed insights into the cellular metabolism of the strains.

-

Through sequencing and expression analyses, we identified unique genes in the strains and neutral sites suitable for stable genome integration of heterologous pathways.

-

We assembled a library of native cyanobacterial promoters and molecular tools to enable precise genetic engineering of these strains.

-

We also constructed genome-scale metabolic models of two strains (PCC11801 and PCC11802) to facilitate simulation of cyanobacterial metabolism.

-

Metabolic Engineering of cyanobacterial strains

Armed with a comprehensive understanding of strain physiology and a robust synthetic biology toolbox, we have successfully engineered 𝘚𝘺𝘯𝘦𝘤𝘩𝘰𝘤𝘰𝘤𝘤𝘶𝘴 𝘦𝘭𝘰𝘯𝘨𝘢𝘵𝘶𝘴 PCC 11801, PCC 11802, and IITB6 for the sustainable production of platform chemicals and biofuels. These products include succinic acid, 2,3-butanediol, mannitol, ethylene, alkanes, and ethanol. These capabilities were enabled by the introduction of heterologous biosynthetic pathways driven by native cyanobacterial promoters, optimized for high expression and product flux. By fine-tuning cultivation conditions, we achieved high product yields in shake flask cultures. Metabolomics enabled us to identify pathway bottlenecks and redirect carbon flux to the target products, guiding rational strain engineering. In parallel, we have addressed challenges of product toxicity through adaptive laboratory evolution (ALE), developing strains with significantly increased tolerance to n-butanol and 2,3-butanediol.

We are currently extending the product scope to include sucrose and recombinant proteins using these robust cyanobacterial strains.

Links

Address

Department of Chemical Engineering,

IIT Bombay

Contact

Lab: +91 22 25767232

Menu

Home

Research

People

Publications

Support

Events

Join Us/Contact

.png)